Design Lounger for Club3

More Than Layers and 3DMZ create futuristic fully 3D printed lounge piece Model.C3 for night club CLUB3 in Haarlem

Model.C3

Model.C3 is a unique, fully 3D-printed lounge piece and a collaboration between studio More Than Layers (MTL) and 3D Makers Zone (3DMZ), two companies based in Haarlem, The Netherlands. Both companies work in the field of industrial 3D-printing, also known as additive manufacturing. MTL is a computational design studio that has expertise in design for digital fabrication, 3DMZ is an innovation hub around industrial 3D-printing who manufactured the entire extra large lounge piece with one of their industrial robotic arm 3D printers.

CLUB3

Recently CLUB3 re-opened in the former cafe area of Patronaat, a renowned cultural venue that has played a pivotal role in Haarlem’s vibrant arts and music scene. Established in 1984, Patronaat has evolved into a multifaceted space, offering a platform for live music, performing arts, and cultural events. CLUB3 consists of three spaces, hence the name; on the ground floor you’ll find the first, the actual nightclub with space for over 150 people. Above it, in the former smoking area, is the second space. This is the brand-new Boiler Stage where the audience can experience a DJ set in an intimate, immersive setting. The third space is the Expo, an exposition area where exceptional artists showcase their works, offering the audience inspiration beyond the realm of music. From the balcony of the Expo visitors have a view of the dance floor of the Boiler.

For the Expo, MTL set out to design a modern and unique 3D-printed piece of furniture that could be used in multiple ways, resulting in Model.C3. The lounge piece serves as a central point for attendees to sit, relax, and engage with the diverse range of exhibitions. The unique design of the Model.C3 adds to the look of the space and encourages people to engage with the stories and ideas behind each exhibition.

Model.C3

Model.C3 is a unique, fully 3D-printed lounge piece and a collaboration between studio More Than Layers (MTL) and 3D Makers Zone (3DMZ), two companies based in Haarlem, The Netherlands. Both companies work in the field of industrial 3D-printing, also known as additive manufacturing. MTL is a computational design studio that has expertise in design for digital fabrication, 3DMZ is an innovation hub around industrial 3D-printing who manufactured the entire extra large lounge piece with one of their industrial robotic arm 3D printers.

CLUB3

Recently CLUB3 re-opened in the former cafe area of Patronaat, a renowned cultural venue that has played a pivotal role in Haarlem’s vibrant arts and music scene. Established in 1984, Patronaat has evolved into a multifaceted space, offering a platform for live music, performing arts, and cultural events. CLUB3 consists of three spaces, hence the name; on the ground floor you’ll find the first, the actual nightclub with space for over 150 people. Above it, in the former smoking area, is the second space. This is the brand-new Boiler Stage where the audience can experience a DJ set in an intimate, immersive setting. The third space is the Expo, an exposition area where exceptional artists showcase their works, offering the audience inspiration beyond the realm of music. From the balcony of the Expo visitors have a view of the dance floor of the Boiler.

For the Expo, MTL set out to design a modern and unique 3D-printed piece of furniture that could be used in multiple ways, resulting in Model.C3. The lounge piece serves as a central point for attendees to sit, relax, and engage with the diverse range of exhibitions. The unique design of the Model.C3 adds to the look of the space and encourages people to engage with the stories and ideas behind each exhibition.

Design

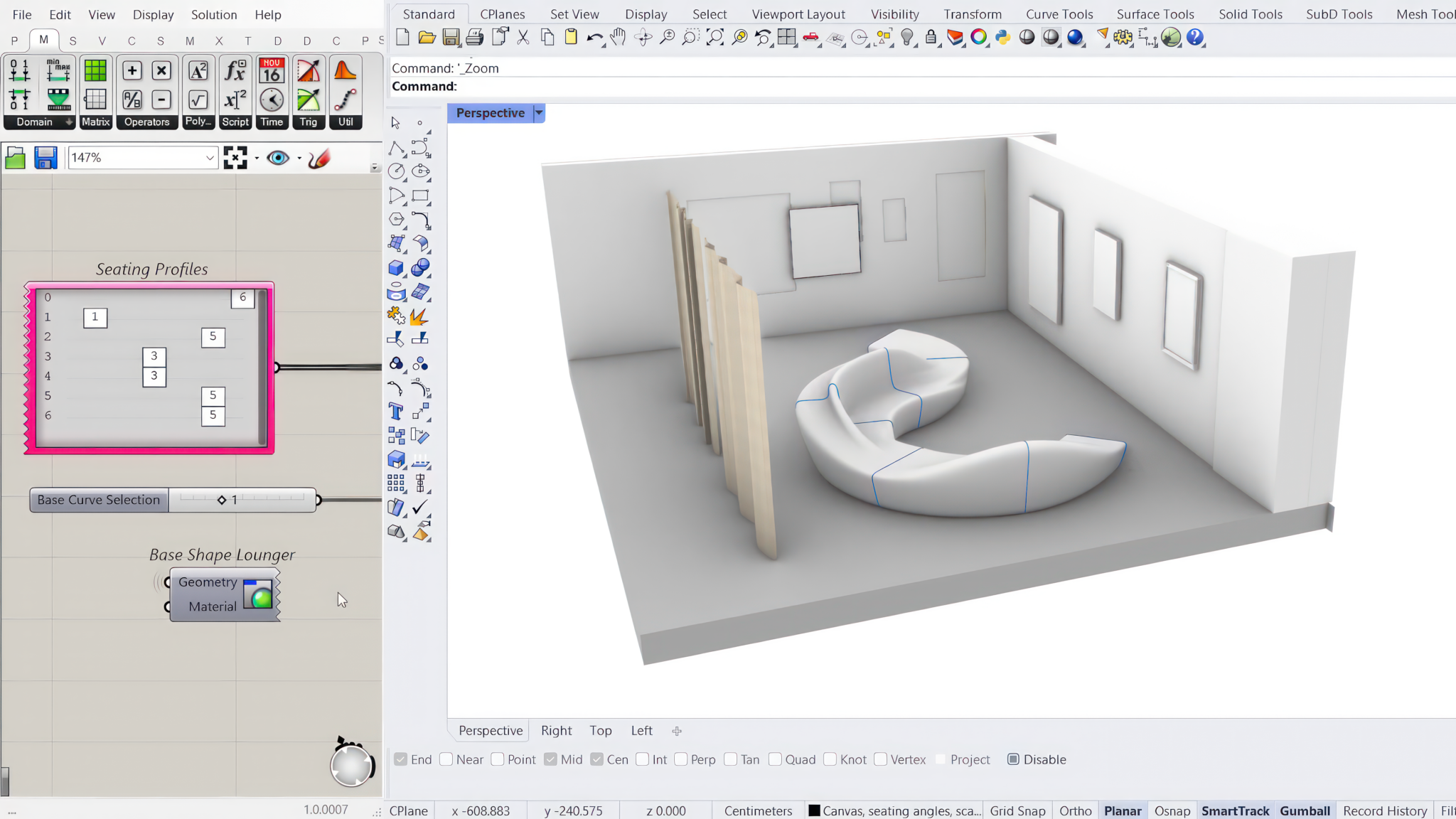

Model.C3’s design is both eye-catching and practical, offering a great balance between style and usability. Its shape is inspired by natural curves, making it not just a piece of furniture, but a part of the room’s decor.The Model.C3’s all-white color makes match well with different environments while highlighting the design’s smooth lines. It’s simple, looks clean, and brings out the sofa’s unique design.

What makes Model.C3 really stand out is its modular design. The pieces easily fit together in different ways, so you can change the setup to suit the occasion or the space you have. Whether you need a large seating area for a group or smaller, separate seats, Model.C3 can be rearranged to fit your needs. This design is all about versatility and making the most out of your space, without compromising on comfort or style.

What makes Model.C3 really stand out is its modular design. The pieces easily fit together in different ways, so you can change the setup to suit the occasion or the space you have. Whether you need a large seating area for a group or smaller, separate seats, Model.C3 can be rearranged to fit your needs. This design is all about versatility and making the most out of your space, without compromising on comfort or style.

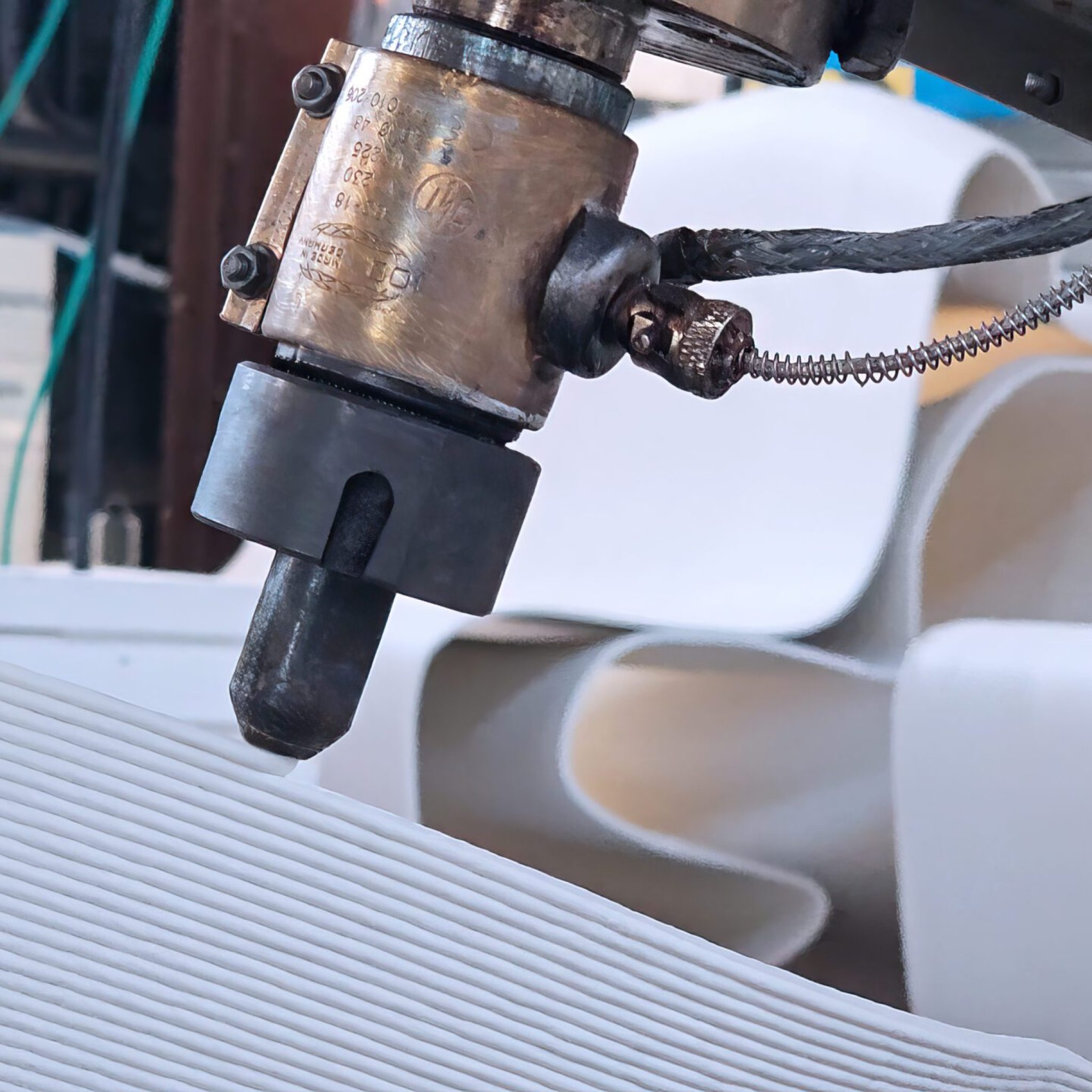

Fully 3D Printed

The Model.C3 project is a big step forward in 3D printing on a large scale, using a robotic arm that goes beyond usual 3D printing methods. Instead of just adding material in flat layers, it can print in various directions. This allows for more intricate designs and stronger structures. The special shape and robustness of Model.C3 come from this advanced printing approach. This project does more than just create a piece of furniture – it highlights how industrial robotic arms could be a game-changer in making all sorts of things, from unique furniture to parts for buildings, in different industries.

This advanced way of printing the Model.C3 wouldn’t be possible without the right software, which is where AdaOne by Adaxis plays a crucial role. AdaOne is specifically designed to control robotic arms used in large-scale 3D printing, transforming designs into printable machine code. It goes beyond basic functions to include part optimization, path planning, process optimization, robotic simulation, program creation, and process monitoring. In projects like the Model.C3, where iterative development is key, optimized process steps are crucial for success. AdaOne played a significant role in this aspect.

This advanced way of printing the Model.C3 wouldn’t be possible without the right software, which is where AdaOne by Adaxis plays a crucial role. AdaOne is specifically designed to control robotic arms used in large-scale 3D printing, transforming designs into printable machine code. It goes beyond basic functions to include part optimization, path planning, process optimization, robotic simulation, program creation, and process monitoring. In projects like the Model.C3, where iterative development is key, optimized process steps are crucial for success. AdaOne played a significant role in this aspect.

New generation of materials

The Model.C3 is 3D-printed with a newly launched material from LyondellBasell, Beon3D. It was chosen for its durability, smooth finish, aesthetic appeal, and recyclability. Beon3D is an innovative product family which allows for the unprecedented design and production of complex, high-quality 3D-printed objects with high dimensional stability and surface quality. The new polypropylene (PP) product range that has been used for the Model.C3 aims at advancing the adoption of additive manufacturing in markets such as transportation, industrial- and consumer goods, and construction.

PP compounds are in many cases the material of choice in industrial manufacturing due to their mechanical properties such as high scratch and chemical resistance, light weight as well as recyclability . Beon3D specifically has been chosen for its high hydrophobicity, acoustic and optical performance, as well as heat resistance.

LyondellBasell combines all of these material advantages with an easy processability for additive manufacturing, such as extrusion-based processes like the robotic arms 3D-printers at 3DMZ.

PP compounds are in many cases the material of choice in industrial manufacturing due to their mechanical properties such as high scratch and chemical resistance, light weight as well as recyclability . Beon3D specifically has been chosen for its high hydrophobicity, acoustic and optical performance, as well as heat resistance.

LyondellBasell combines all of these material advantages with an easy processability for additive manufacturing, such as extrusion-based processes like the robotic arms 3D-printers at 3DMZ.

Closed-Loop Design

The Model.C3 is designed with a closed-loop system in mind, allowing for easy recycling and re-use of the Beon3D material.

If the lounge piece reaches its end-of-life at CLUB3, 3DMZ plans to repurpose the material into new designs. This ensures that the materials will be reused, repurposed, and reintegrated into the 3D-printing production cycle, minimizing waste and promoting a circular economy.

If the lounge piece reaches its end-of-life at CLUB3, 3DMZ plans to repurpose the material into new designs. This ensures that the materials will be reused, repurposed, and reintegrated into the 3D-printing production cycle, minimizing waste and promoting a circular economy.

See more projects that deserve your attention.

Inspired? Work with us